Polishing / Sand Blasting Plastic Injection Moulding Process For Japanese Car Parts

| Place of Origin: | Guangdong, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Polishing / Sand Blasting Plastic Injection Moulding Process For Japanese Car Parts

<span

Polishing / Sand Blasting Plastic Injection Moulding Process For Japanese Car Parts

Plastic Injection Mould For Japanese Car parts

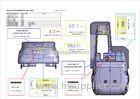

Mould Detail

| Mould material | P20 steel, 718, 2738, H13, NAK80, 2344, 2343, S136, etc . |

| Runner | Cold runner. Hot runner: Yudo/DME/HASCO |

| Steel Of Cavity & Core | DIN1.2316/DIN1.2738/DIN1.2344/718/P20(optional) |

| Mould Base Standard | HASCO, DME, LKM |

| Specification drawings | Pro/E, Auto CAD, Solidwork, CAXA UG, CAD/CAM/CAE. |

| Precision machining | CNC, milling machine, drilling machine, numerical lathe, all types of lathe |

| Surface finish process |

polishing, sand blasting, heat treatment, painting, powder coating, anodizing, electroplating, mirror polishing . |

| Shaping mould | injection mould |

| Mould life | above 500000-1000000 shots and up |

| Service | OEM service available, good after-sales service . |

| Lead time | 4-7 weeks, 40 days or according to the real situation . |

| Plastic material | PP, ABS, HDPE, PC, PVC ect |

Mould Processing

| 1.Quote | According to sample, drawing and specific requirement. |

| ↓ | |

| 2.Discussion | Mold material, cavity number, price, runner, payment, etc. |

| ↓ | |

| 3.S/C Signature | Approval for all the items |

| ↓ | |

| 4. Advance | Pay 50% by T/T |

| ↓ | |

| 5.Product Design Checking |

We check the product design. If some position is not perfect, or can not be done on the mould, we will send customer the report. |

| ↓ | |

| 5.Mould Design |

We make mould design on the basis of confirmed product design, and send to customer for confirmation. |

| ↓ | |

| 6.Mold Tooling | We start to make mold after mold design confirmed |

| ↓ | |

| 7.Mold Processing | Send report to customer once each week |

| ↓ | |

| 8.Mold Testing | Send trial samples and try-out report to customer for confirmation |

| ↓ | |

| 9. Mold Modification | According to customer’s feedback |

| ↓ | |

| 10.Balance settlement | 50% by T/T after the customer approved the trial sample and mould quality. |

| ↓ | |

| 11.Delivery | Delivery by sea or air. The forwarder can be designated by your side. |

FAQ

Q:what is your trade term?

A:usually EXW or FOB ShenZhen

Q:what is your payment term?

Related Search

Find more related products in following catalogs on Hisupplier.com

Company Info

YONGHETHAI TECHNOLOGY COMPANY [China (Mainland)]

Business Type:Manufacturer

City: Shenzhen

Province/State: Guangdong

Country/Region: China (Mainland)

You May Like:

Sitemap XML

About HiSupplier Help Center Customer Service Friend Links Site Map Archives

Browse by: China Suppliers - Hot Products - Products Directory - Offers Directory - Suppliers Directory - Buyers Directory

Language Option: العربية - Nederlands- Français- Deutsch- Italiano- 日本語- 한국의- Português- Pусский- Español