Hot Runner or Cold Runner Plastic Injection Mould Plastic Injection Tooling

| Place of Origin: | Guangdong, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

2014 New Technology Custom Plastic Injection Mould&nb

2014 New Technology Custom Plastic Injection Mould

Specifications

Injection Mould

1.ISO 9001:2008 Certificated.

2.HASCO.DME.LKM Standard.

3.High Quality and servise.

Shenzhen Yonghe Tai Technology Co.,LTD is a professional in making mold and plastic products, If you need mold or products, we can help you to do this, but first please send us more and more information about the mould what you have. Like sample photo, sample size, what's the sample material and what kind of steel you want to make the mould, When we get this information, we can send the mould quote andTechnology analysis.

Our Factory Advantages

1. We are one_stop manufacturer of plastic mold and finished plastic products. Specialized in mold design, making plastic mold, injection process,spraying and silk printing.one-stop services for more than 9 years.

2. We can make molds and plastic products according to your drawings or samples.

3. Our die include: auto parts, household appliances, medical equipment, House application products, electronic and electrical appliances, handicrafts and engineering construction etc...

4. Injection products material character:soft plastic,hard plastic,transparent,ect.

5. Common used plastic material:ABS,PC ,TPR,TPU,PMMA,POM,PA,PP,BPT etc.

2014 New Technology Custom plastic Injection Mould

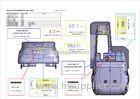

Injection Mould discription

| We promise | All customer-centric, never for short-term profit, and sell long-term benefits | |||||||||

| We produce |

Mold, prototype, injection molding, product assembly, surface printing, spraying the surface integration |

|||||||||

| Pls provide | 2D, 3D, samples, or the size of the multi-angle pictures | |||||||||

| Mould Time | 35 Days | |||||||||

| Product time | 7-15 Days | |||||||||

| Moud precision | 0.1mm | |||||||||

| Mould life | 50-100 million shots | |||||||||

| Mould cavity | One cavity, multi-cavity or same different products be made together | |||||||||

| Mould material | P20,2738,2344,718,S136,8407,NAK80,SKD61,H13 | |||||||||

| Runner system | Hot runner and cold runner | |||||||||

| Base material | P20,2738,2344,718,S136,8407,NAK80,SKD61,H13 | |||||||||

| Finish | Pitting the word, mirror finish, matte surface, striae | |||||||||

| Standard | HASCO, DME or dependent upon | |||||||||

| Main thechnology | Milling, grinding, CNC, EDM, wire cutting, carving, EDM, lathes, surface Finish, etc. | |||||||||

| Software | CAD,PRO-E,UG Design Time: 1-3 days (normal circumstances) | |||||||||

| Product material |

ABS,PP,PC,PA6,PA66,TPU,POM,PBT,PVC,HIPS,PMMA,TPE,PC/ABS, TPV, TPO, TPR,EVA,HDPE,LDPE,CPVC,PVDF,PPSU.PPS. |

|||||||||

| Quality system | ISO9001:2008 | |||||||||

| Equipment | CNC,EDM,Cutting off Machine,plastic machinery,etc | |||||||||

Mould Trade Process :

|

1.R&D |

We support customer R&D. Make the files or improve the design if you needed |

|

↓↓↓ |

|

|

2.Quotation Making |

Mould Quotation will be finished in 1day according to information we get |

|

↓↓↓ |

|

|

3.Negotiation |

The quality ,price ,material,delivery time .payment item.ect |

|

↓↓↓ |

|

|

YONGHETHAI TECHNOLOGY COMPANY [China (Mainland)]

Business Type:Manufacturer | |