Electronic Products Mould Plastic Injection Moulding Services

| Place of Origin: | Guangdong, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

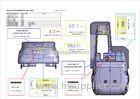

Electric Switch Socket Mould Plastic Parts Electronic Products Mould

Specifications

Socket mould

1.Timely Service Feedback

2.Precise Machine (CNC, EDM, etc)

3.High-efficiency Project Management

Shenzhen Yonghe Tai Technology Co.,LTD is a professional in making mold and plastic products, If you need mold or products, we can help you to do this, but first please send us more and more information about the mould what you have. Like sample photo, sample size, what's the sample material and what kind of steel you want to make the mould, When we get this information, we can send the mould quote andTechnology analysis.

Our Factory Advantages

1. We are one_stop manufacturer of plastic mold and finished plastic products. Specialized in mold design, making plastic mold, injection process,spraying and silk printing.one-stop services for more than 9 years.

2. We can make molds and plastic products according to your drawings or samples.

3. Our die include: auto parts, household appliances, medical equipment, House application products, electronic and electrical appliances, handicrafts and engineering construction etc...

4. Injection products material character:soft plastic,hard plastic,transparent,ect.

5. Common used plastic material:ABS,PC ,TPR,TPU,PMMA,POM,PA,PP,BPT etc.

Electric Switch Socket Mould Plastic Parts Electronic Products Mould

Injection Mould discription

| 1:Name: | Plastic Injection Part Mold | |||||||

| 2.Product Material: | ABS, PVC, PC, PMMA, PE, POM, PA, TPU etc. | |||||||

| 3. Mould Cavity: | Single cavity, Multi Cavity | |||||||

| 4.Mould Base: | LKM,HASCO | |||||||

| 5.Runner: | Hot/Cold as per your requirement | |||||||

| 6.Mould Core Steel: | #45 steel, 718, P20,NAK80,S136 etc. | |||||||

| 7.Mould Life: | 500,000-1,000,000 shots gurantee | |||||||

| 8.Mould leadtime: | 3-6weeks | |||||||

Custom Your Own Mould

Mould Trade Process :

| 1.Quote | According to sample,drawing and specific requirement. | ||||||||

| ↓ | |||||||||

| 2.Discussion | Mold material,cavity number,price,runner,payment,etc. | ||||||||

| ↓ | |||||||||

| 3.S/C Signature | Approval for all the items. | ||||||||

| ↓ | |||||||||

| 4.Advance | Pay 50% by T/T | ||||||||

| ↓ | |||||||||

| 5.Product Design Checking | We check the product design.If some position is not perfect,or can not be done on the mould,we will send customer the report. | ||||||||

| ↓ | |||||||||

| 6.Mould Design | We make mould design on the basis of confirmed product design,and send to customer for confirmation. | ||||||||

| ↓ | |||||||||

| 7.Mold Tooling | We start to make mold after mold design confirmed. | ||||||||

| ↓ | |||||||||

| 8.Mold Processing | Send report to customer once each week. | ||||||||

| ↓ | |||||||||

| 9.Mold Testing | Send trial samples and try-out report to customer for confirmation . | ||||||||

| ↓ | |||||||||

| 10.Mold Modification | According to customer'feedback. | ||||||||

| ↓ | |||||||||

| 11.Balance Settlement | 50% by T/T after the customer approved the trial sample and mould quality. | ||||||||

| ↓ | |||||||||

| 12.Delivery | Delivery by sea or air.The forwarder can be designated by your side. | ||||||||

Related Search

Find more related products in following catalogs on Hisupplier.com

Company Info

YONGHETHAI TECHNOLOGY COMPANY [China (Mainland)]

Business Type:Manufacturer

City: Shenzhen

Province/State: Guangdong

Country/Region: China (Mainland)